Innovative Cooling Tower Technology – High Efficiency, Energy Savings, and Water Conservation

A Cooling Tower is an essential heat dissipation system widely used in industries such as manufacturing plants, power stations, and large-scale cooling systems. These industries demand high energy consumption to regulate temperature effectively. The Octagon Cooling Tower is an advanced design that enhances cooling performance, reduces noise levels, and minimizes water loss, making it a superior choice compared to traditional crossflow (rectangular-shaped) Cooling Towers, which often face limitations in airflow distribution and operational efficiency.

Key Features of the Octagon Cooling Tower

✅ Minimized Water Loss – Built-in drift eliminators effectively prevent water droplets from being carried away by airflow.

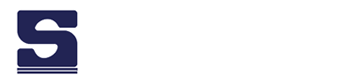

✅ Low-Noise Fan Operation – Designed with direct-drive low-speed motors, eliminating the need for gear reducers or pulley-belt systems, reducing vibration, noise, and maintenance costs.

✅ Superior Cooling Performance – Utilizes Cross Flow technology, where air enters from all four sides, ensuring uniform heat exchange and rapid temperature reduction.

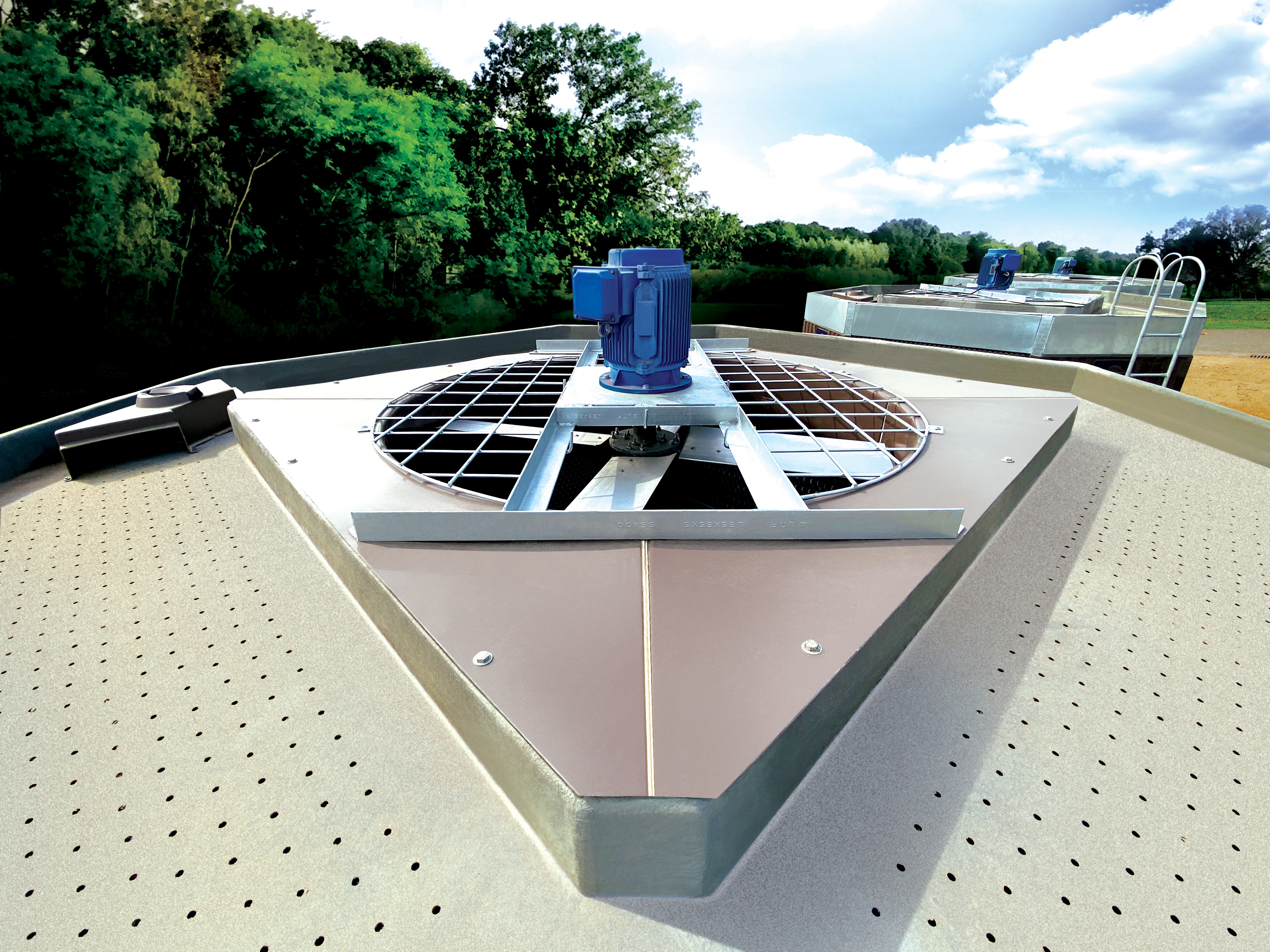

✅ Sleek Design with Concealed Piping – Integrated internal piping reduces installation costs, eliminating the need for external pipes while maintaining a modern and organized system appearance.

✅ Easy Maintenance – Features an accessible service door for monitoring water levels, replacing float valves, and cleaning strainers without requiring entry into the Cooling Tower, improving maintenance convenience and safety.

✅ Low-Noise Fan Operation – Designed with direct-drive low-speed motors, eliminating the need for gear reducers or pulley-belt systems, reducing vibration, noise, and maintenance costs.

✅ Superior Cooling Performance – Utilizes Cross Flow technology, where air enters from all four sides, ensuring uniform heat exchange and rapid temperature reduction.

✅ Sleek Design with Concealed Piping – Integrated internal piping reduces installation costs, eliminating the need for external pipes while maintaining a modern and organized system appearance.

✅ Easy Maintenance – Features an accessible service door for monitoring water levels, replacing float valves, and cleaning strainers without requiring entry into the Cooling Tower, improving maintenance convenience and safety.

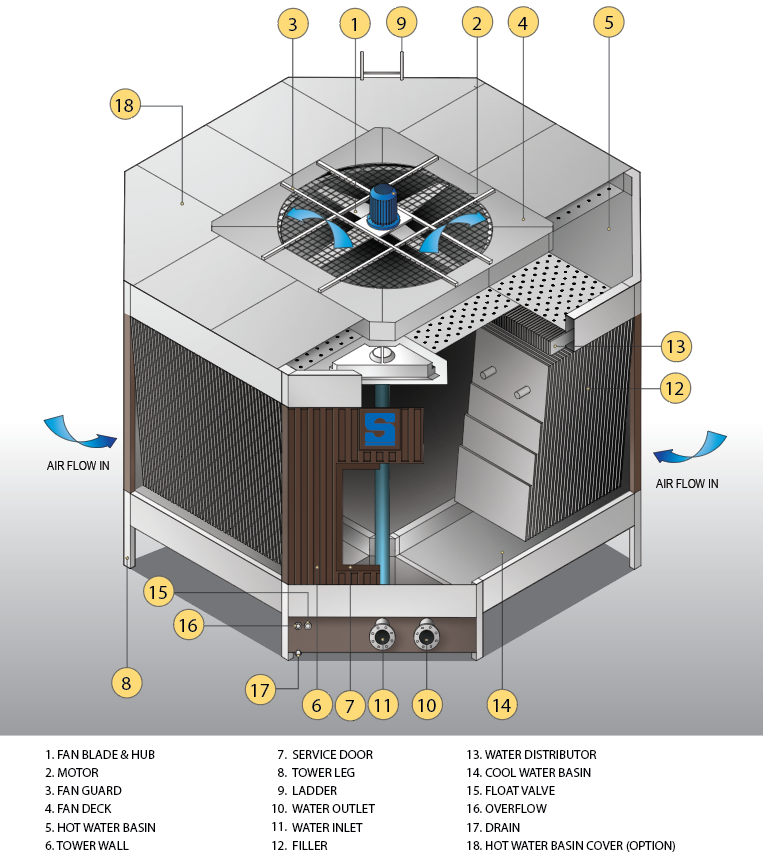

How the Octagon Cooling Tower Works

Hot water from the cooling system is delivered to the Octagon Cooling Tower, where it flows into a hot water basin located at the top of the tower. The water is evenly distributed over the filler media, which significantly increases the heat exchange surface area. Simultaneously, cool air is drawn from all four sides through a high-efficiency fan mounted at the top, creating an effective Cross Flow heat exchange process.

Once the heat exchange is complete, the cooled water collects in the bottom basin before being recirculated back into the cooling system. The warm air, now carrying the extracted heat, is expelled through the exhaust vent at the top, ensuring a continuous and stable cooling process.

Beyond providing rapid temperature reduction, the Octagon Cooling Tower incorporates a specialized drift eliminator system, which prevents water droplets from being carried away by airflow. This design reduces water loss, minimizing the need for frequent water replenishment and significantly lowering operational costs.

Why Choose the Octagon Cooling Tower?

With its modern, efficient design, the Octagon Cooling Tower is not only a cost-effective solution but also a low-maintenance, energy-saving cooling system. Its advanced water conservation system, high-performance heat exchange, and ease of maintenance make it the ideal choice for industries requiring high-efficiency Cooling Towers. Whether for industrial plants, commercial buildings, data centers, or power plants, the Octagon Cooling Tower ensures superior cooling performance and long-term reliability.

Upgrade or Install a New Cooling Tower? Contact Our Experts Today!

If you are looking for a high-efficiency Cooling Tower solution that offers energy savings, reduced maintenance, and water conservation, our experts are ready to assist you in selecting the best option for your business needs.

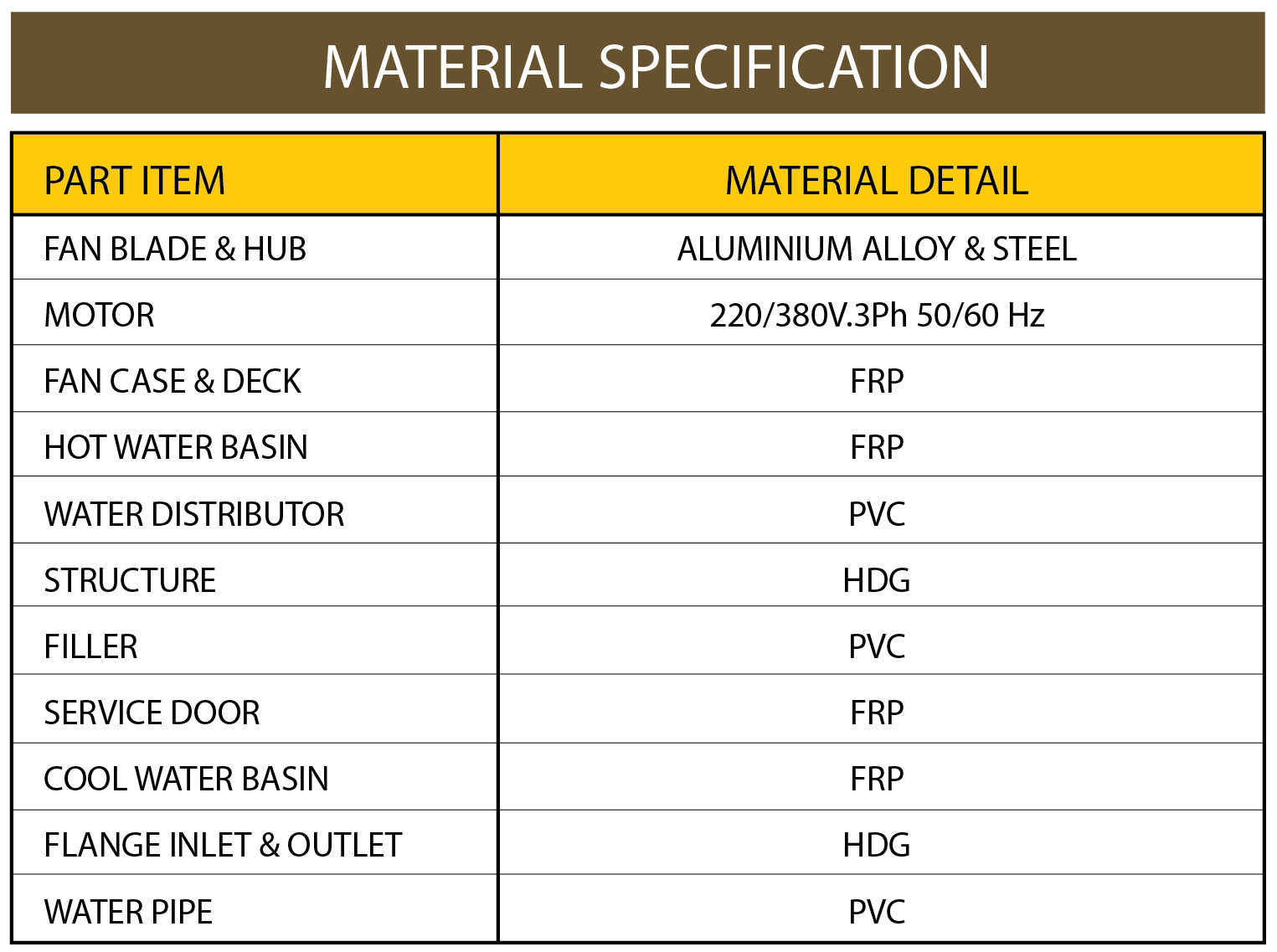

TOWER STRUCTURAL DETAILS

Octagon Crossflow Cooling Tower OTG